Crafted with Accuracy. Delivered with Excellence

With its unmatched accuracy and unparalleled speed, laser cutting services is transforming manufacturing and design industries. This technology serves myriad sectors, spanning from delicate artistic works to strong industrial parts. In this article, we cover everything you need to know about laser cutting, its innovations, history, applications, and future prospects.

Laser cutting services technology has achieved amazing precision, achieving tolerances of 0.001 inches. Such precision is necessary in the aerospace and medical device industries. At metacrafto, we offer the most affordable prices for metacrafto Laser cutting.

With us, you can get advanced high precision metacrafto Laser cutting services. For different business verticals, we provide tailored solutions. Armed with powerful tools and a highly trained team, we fulfill any order no matter how tiny or large, intricate or complex – with laser sharp accuracy. Rest assured, we stand by your expectations.

Laser Beam Generation: The focusing lens receives a directed laser beam from a generator which simultaneously produces a lazer beam.

Material Interaction: The laser concentrated on the material’s surface gets absorbed, and the energy converts into heat. This intense energy either vaporizes, burns, or melts the material.

Cutting or Engraving: With the aid of a CAD (Computer-Aided Design) file, laser follows a specified path to cut or engrave the material with great precision.

Blower or Gas Assist: While cutting, some gasses such as nitrogen, air, or oxygen can be employed to blow the heated material to improve cutting and to create cleaner edges.

Precision and Accuracy: With laser cutting, the efficiency is guaranteed accuracy of production as it allows for very intricate and elaborate designs to be reproduced. Finer and more complex shapes and patterns are achieved with laser cutting services due to the design precision.

Minimal Material Waste: economical efficiency because of the small width of the laser beam that is used as cutting tool, there is minimal material waste.

Reduced Wear: As a contactless technique, the cutting process does not result in rough edges, smooth clean edges with negligible burrs are produced.

Consistency: There is no physical tool utilized in laser cutting; hence, there is no tool wear associated with the method, preserving its reliability and precision.

Efficiency: Especially when dealing with bulk orders, the process is usually quicker than other, more traditional methods.

Capability: Unlike conventional methods, with the aid of a computer and sophisticated software, a laser can easily execute delicate and elaborate designs which are particularly intricate and may be difficult to cut.

To fulfill varying business objectives, we have different laser cutting services:

Metal Laser Cutting

Ideal for stainless steel, aluminum, brass, and copper.

Ensures clean edges, minimal heat damage, and precision cuts.

Customized Laser Cutting Solutions

Tailored services for unique design requirements.

Prototypes, small-batch production, and bulk orders available.

At MetaCrafto, we apply advanced laser cutting techniques, which guarantee sharp and exact cutting for marvels of precision and intricate shapework. With unrivaled reduction laser finishing requirements accuracy, we meet the demands of shaping complex and detailed designs.

As a result of employing laser cutting, MetaCrafto achieves removing any unnecessary costs which upholds minimal material wastage and translates to clean and precise cuts. With no skipping out on quality regardless of whether you seek small dealings or bulk orders, we offer affordable competitive rates.

Due to the non-contact mechanism of laser cutting, materials are not marred by any surface irregularities such as burrs, which results in smooth contours which eliminates post-processing work for almost every project. In turn, this leads to a clean and high-quality finishing.

Choose MetaCrafto for precise, high-quality laser cutting that guarantees durable, intricate designs. Our custom solutions and efficient processes ensure your projects stand out with exceptional craftsmanship.

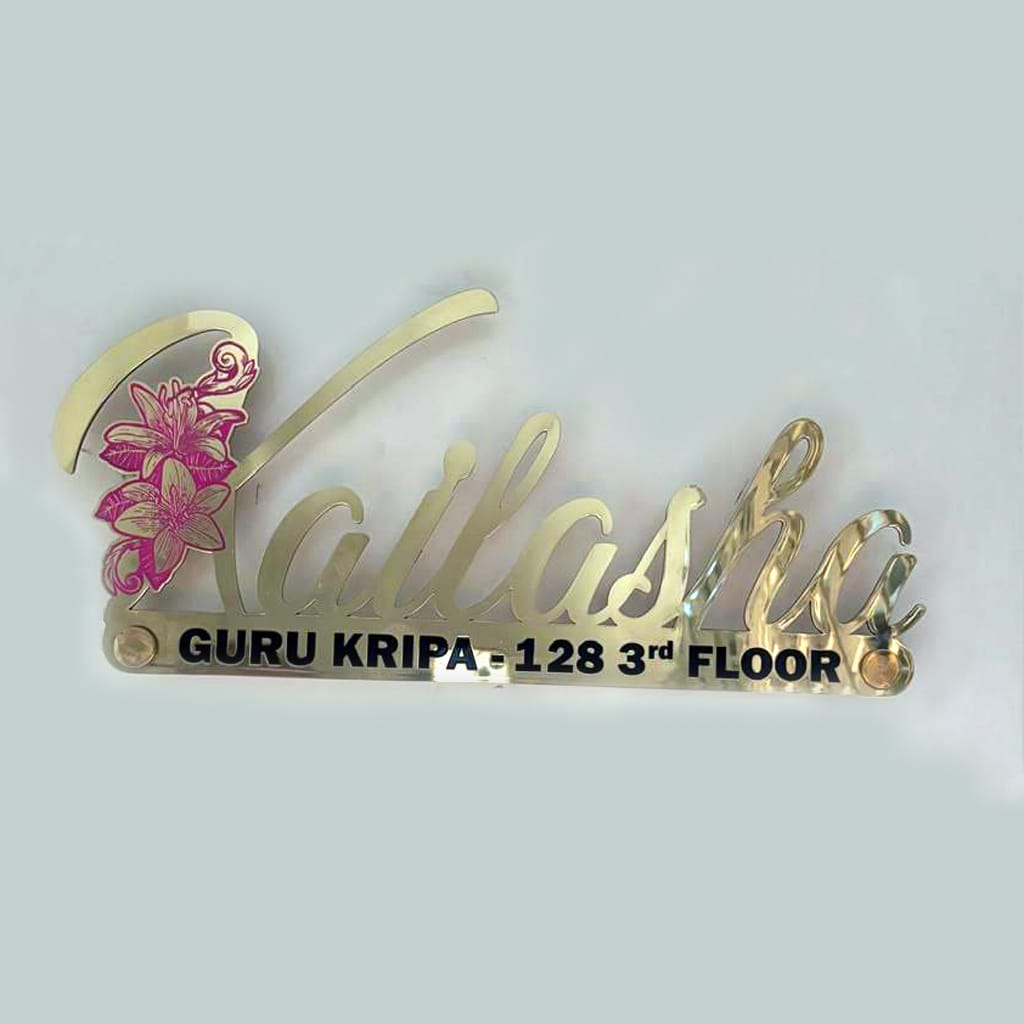

Our Product Image

Laser cutting is a procedure that utilizes a powerful laser beam to cleanly and carefully cut or engrave materials. It does this by concentrating the laser on the surface of the material, which either melts burns, or vaporizes the portions to create a cut.

Laser cutting is well known for its accuracy. It can achieve tolerances as close as ±0.1 mm and even lower based on the material and its thickness. This makes it highly suitable for complex geometries and intricate designs.

The main differences are:

Accuracy: Traditional Methods Cannot Compete With The Precision Offered By Modern Workshops.

Material Waste: Due To Its Narrow Cut Width, There Is Less Material Waste Produced When Compared To Traditional Services.

No Contact: Unlike mechanical methods of cutting that rely on lexing materials, laser cutting does not make contact with the piece, protecting it from any deformation or wear.

Speed: For Complex Designs Or Large Volumes, Laser Cutting Is Faster.

Laser cutting saves time and money considering the faster order fulfillment, less material squandered, and lower need for post-assembly work for small to medium business runs. However, larger scale projects might not benefit as much as traditional methods would be cheaper due to lower initial expenditures.

With laser cutting, everything is sliced through the material and parts are separated out. Encompassed within laser engraving is marking and burning the material's surface without going through to the other side. Text, logos, and images can also be made using laser engraving.

With laser cutting, anything can be made extremely precise which is why it is amazing with intricate designs. Patterns and details that are complicated to do using traditional methods can easily be done with elaborate precision through a laser.

Yes to both. It can be used for advanced design rough drafts as well as large scale production. It is a versatile method enabling fast design changes as well as high volume cutting which makes it great for design iteration and refinement.

For laser cutting, you can submit designs in vector formats (.AI,.DXF, *.SVG). As long as you provide a design file, most laser cutting service providers will complete the product according to your design.